Insights

5 Technologies Transforming Supply Chains Today

2020 has been a mystifying year for retailers, warehouse operators, manufacturers, and logistics companies. The pandemic caused big shifts in consumer buying behaviour that will be irreversible and impact supply chains for the foreseeable future.

We have seen exciting shifts take shape in the industry, including the adoption of big data, AI, sustainability, and omnichannel marketing. These highlights the vital role of technology in supply chain orchestration, beyond stock-taking and delivery to other aspects like process automation, customer service and security management.

The application of these has grown beyond stock-taking and delivery to other aspects like process automation, customer service and security management.

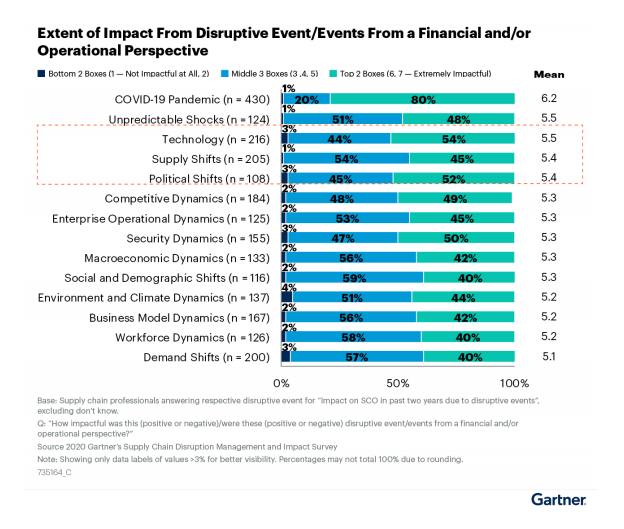

According to a 2020 Gartner survey of supply chain professionals, the impact of technology and supply shift are two of the greatest operational disruptions following unpredictable events, such as COVID.

Needless to say, logistic companies and businesses heavily reliant on shipping and logistics need to recalibrate and develop innovative strategies to sustain the ever-changing landscape.

From automated warehousing technology to real-time delivery solutions, here are the 5 technologies transforming the supply chain logistics industry for 2021:

1. Robotic Goods-to-Person (G2P) system – More than the short-term value.

Administration costs in cross border shipments are estimated to account for a fifth of the total cost of transportation. The math of this in a 50 trillion dollar global supply chain industry is profound, resulting in imperative digitisation of systems that provide more than short-term value.

One such in recent years is – a form of Robotic goods-to-person automation (a.k.a G2P systems) that has increased in relevance in the market. From meticulous tracking of employee movement to different argumentative approaches, the adoption of G2P systems come in several forms.

Although invasive approaches of tracking employees’ every move are evermore frowned upon, something like a human-virus-resistant robot that promotes social distancing and drives notable productivity improvements makes it a win-win in the given global circumstances.

Advanced systems also offer additional benefits, such as improved storage density.

Thus, in their quest to have ‘pandemic-proof’ warehouse operations, the supply chain companies optimise themselves, shrinking their warehouse sizes and looking into new fulfilment solutions that let them do more with less and get goods to customers faster.

2. 360-Degree View of The Complete Supply Chain Network – The Rise of Real-Time Visibility Platforms.

Vulnerabilities in global supply chains were disclosed in the past year. It was evident that visibility and transparency in all aspects of the supply chain are key to preparedness and responsiveness during crises. The lack can therefore result in supply chains being disorganised, costly and inefficient.

The solution is an exclusive Real-Time Transportation Visibility Platform (RTTVPs) or a multi-function platform, improving customer visibility. These provide real-time insights into orders and shipments as the goods leave their warehouse premise.

Usually owned and managed by third-party software vendors, RTTVPs gather data through integration (e.g. API or EDI) with transport systems, direct feeds from telematics like the in-cab or other media (e.g. mobile or smartphone).

In numbers, by 2023, 50%ꟹ of global product-centric enterprises will have invested in platforms that provide real-time transportation visibility, with complementary features that support transportation management, warehouse management, yard management, and fleet management.

3. End-to-End (E2E) Control Towers – Command Centres for Efficiency Gains and Savings in Supply Chain, Logistics & Transportation.

A control tower system attempts to keep sight of the external supply chain environment, with “end-to-end” (E2E) visibility being the ultimate goal. However, more often than not, they are functionally siloed, resulting in revenue and data leaks.

The solution entails the plan-source-make-deliver of supply chain operations with the orchestration of technology to evolve into one-system E2E visibility, E2E process orchestration and E2E aligned decision making.

With the technology advancements, growth of multi-party, consumer-driven networks advanced control towers now enables sustainable, collaborative and powerful AI capabilities to move beyond decision-support to decision-making and autonomous control, in addition to real-time visibility.

Albeit in its nascent stages, the forecast numbers also indicate slow adoption, potentially due to mindset and cultural obstacles.

All said and done the possibilities lean towards having a properly configured and comprehensively used, cohesive platform to support an End-to-End control tower well integrated on top of other core SCM application and data analysis functions.

4. AI, Advanced Analytics and Emerging Technologies – Efficient, Visible, Resilient Supply Chains.

In today’s fast-paced world, the capability to rapidly evaluate multiple scenarios and drive smart business decisions can differentiate between success and failure. All translate to visibility being the necessary foundation and first step for organisations.

So, how do can businesses analyse and predict the data, providing scenario-based options for the next best action, transform them into actionable insights simulating and responding to accelerate your supply chain initiatives?

The answer is simple – Technology.

To elaborate, here are some of the top technologies poised to overhaul supply chain operations:

Blockchain:

There is an increasing demand for software vendors to leverage and benefit from the technology advancements, digitise processes and pass along innovation to their customers.

This innovation can be found in the next generation of digital trust technology—delivering secure solutions, reducing cost, and increasing trust and transparency, through Blockchain.

While primarily associated with cryptocurrencies, blockchain, the distributed ledger technology, also ranks high on the list of technologies poised to ensure traceability and greater accountability across the entire supply chain, mitigating inherent risks of fraud and loss.

Artificial Intelligence/ Machine Learning:

Large-scale automation is synonymous with AI and ML across industries.

In the Supply Chain industry, particularly, 37%ꟹ of organizations have executed AI in some form and it is predicted by 2024, 50%ꟹ of supply chain organisations will invest in applications that support artificial intelligence (AI) and advanced analytics (AA) capabilities.

Businesses that use AI and AA technology in their supply chain addresses foundational areas such as data quality or combining disparate silos or strategic objectives such as migrating to automated, flexible and more intelligent applications.

The results have seen remarkable improvements in inventory management, customer experience, supplier selection, and staff productivity.

Internet of Things(IoT):

A simple yet reliable Internet of Things plays a significant role in supply chain visibility. Location, motion, shock and other sensors attached to modes of transportation offer various information in real-time.

With IoT advancements, businesses can now automatically manage their inventory and stock movement in an improved manner. The system works by gathering big data into a central system for analysis. From the result, supply chains can derive valuable insights.

5. Dedicated technology roles – human intervention for process and technology integration inside supply chain organizations.

In order to stay ahead and ensure seamless digitalisation of the supply chain, businesses need to fundamentally push the integration of process and technology like 5G, mature IoT, AI, et al. in the supply chain strategy and design.

This influx and advancement of technology within the supply chain and logistics ecosystem has created opportunities for equally skilled human resources to lead sophisticated technology teams within the supply chain organizations directly.

The numbers indicate the same; by 2025, more than 50%ꟹ of supply chain organizations will have a technology leadership role reporting directly to the CSCO.

Conclusion:

Overall, the world, supply chain and logistics industry, are up for an extremely transformative, rapidly moving and exhilarating future. There’s no doubt that processes have become quicker, smarter, customer-oriented, and sustainable.

AI, blockchain, and IoT technologies will automate, make operations simpler, and transform into the digital supply chain, which is largely traditional. The latest technologies on security, transparency, market prediction, big data analytics, flexible and agile supply chain processes will continue developing as the year closes.

Being informed about this evolving landscape will help minimize supply chain disruptions, making business ready and facing unforeseen challenges of the future.

ꟹ GARTNER SUPPLY CHAIN PREDICTIONS 2021