Insights

Data in supply chain management – Benefits and Implications

“Data is what you need to do analytics. Information is what you need to do business”. In a world where businesses of all sizes aim to be at the top in their respective fields, John Owens’s quote seems perfect and befitting of the time. Supply chain and logistics is no different.

Of course, technology is at the centre of it all. Although 72% of supply chain organisations view technology as a source of competitive advantage, only 47% manage supply chain management(SCM) technology horizontally and holistically across functional domains.

A whopping $50-trillion industry, this, the volume of data churned each day, cannot be efficiently managed by simple spreadsheets. From improving delivery time to reducing costs, optimal utilisation of data helps supply chain business units resolve severe strategic issues, both at the demand (the shipper) side and the supply (the carrier) side.

But first, what is data in Supply Chain and how has it evolved over the years?

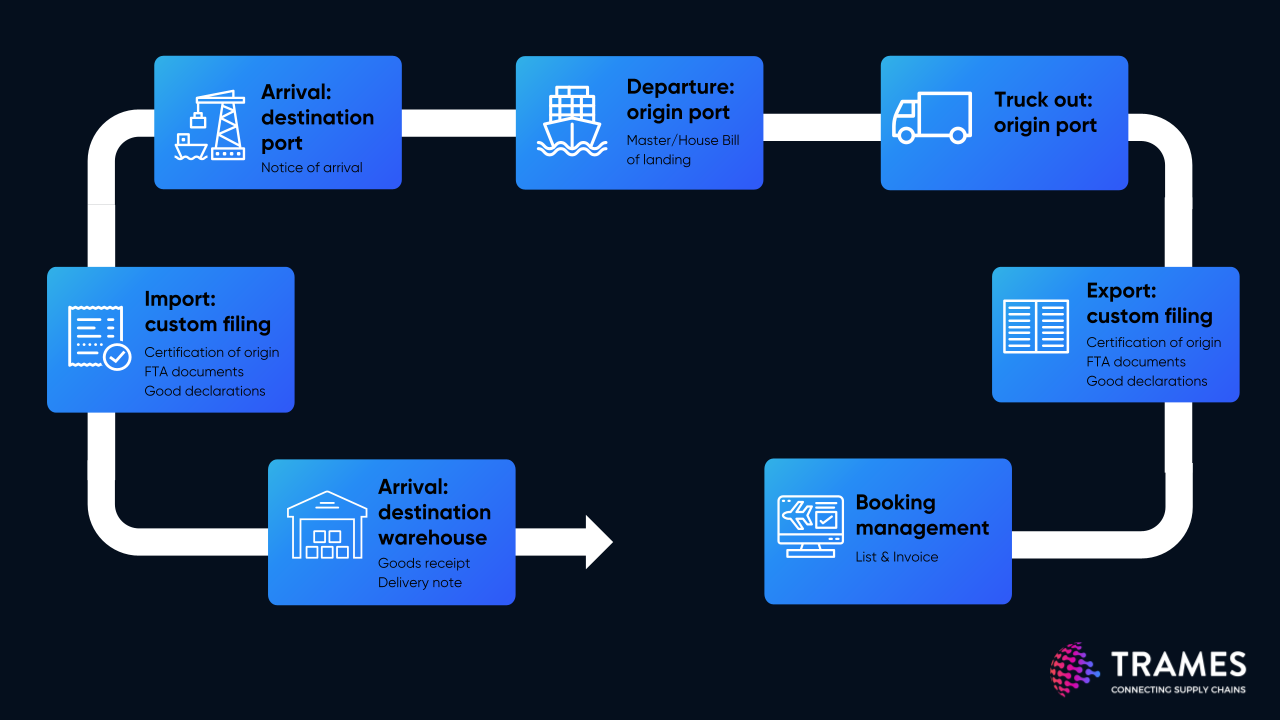

Data is generated in every milestone of the supply chain process and is detailed in documents such as booking confirmation details, packing lists, forwarder agent note, invoice, certificate of origin, free trade agreement (FTA) documents, good declarations, to name a few. However, data that are often not captured are more useful than ever in identifying the gaps and optimising the supply chain.

Figure 1: Stages of the freight movement process (export to import) and associated documents.

As supply chains face higher customer expectations, demand for competitive pricing and costs of managing disruptions, the importance of such data cannot be underestimated. Full monitoring of the supply chain processes can yield clear and complete data for analysis, financial reporting, and evaluating supply chain operations.

Evolution of Data in The Supply Chain

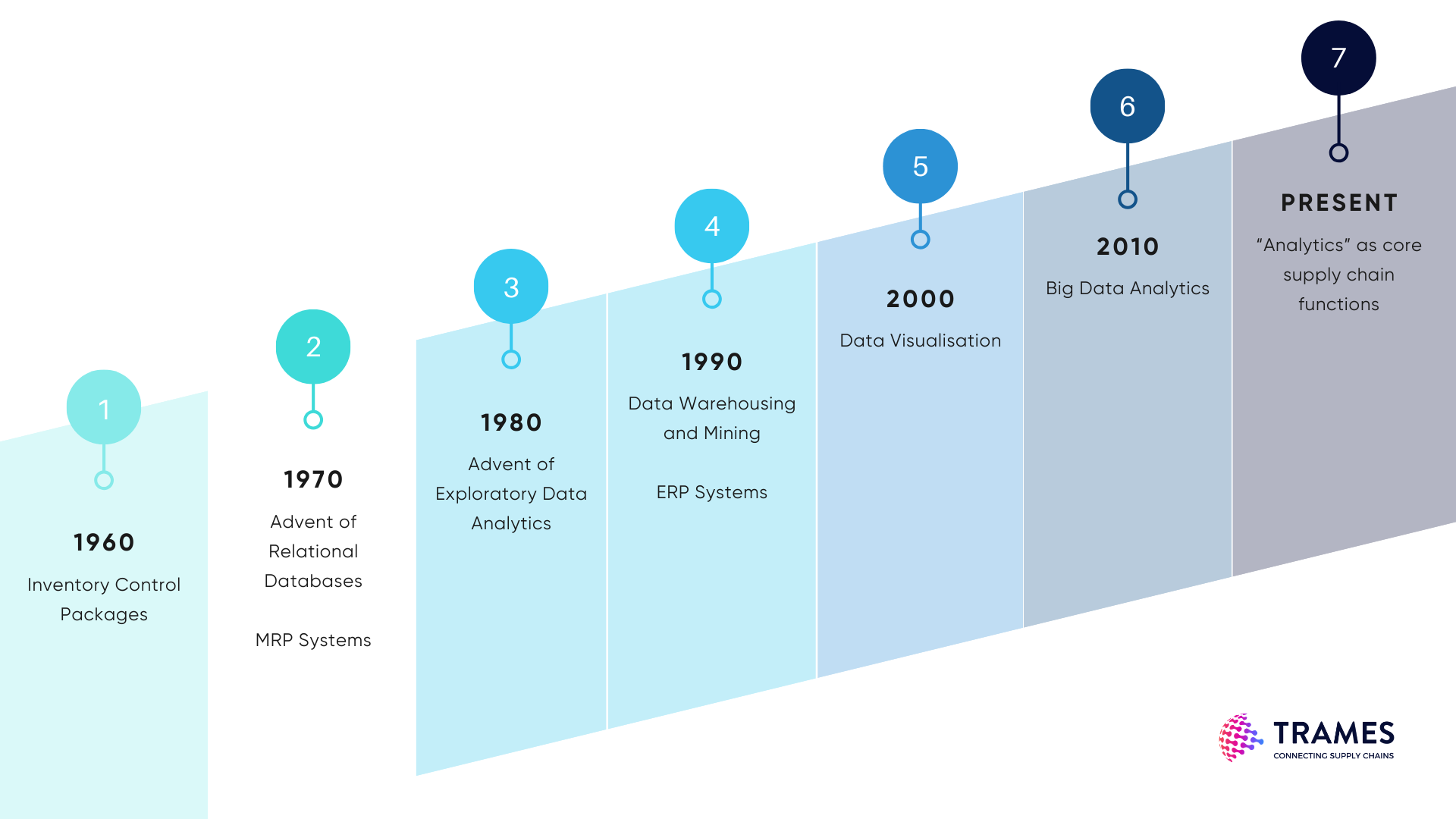

Usage of data in logistics and supply chain has transformed over the years; from manual data storage systems like plain spreadsheets and physical documents to partially processed and semi-organised data from EDI (Electronic Data Interchange) & ERP (Enterprise Resource Planning) systems.

With the advancement of technology, each of these systems has helped businesses manage end-to-end supply chain data. These data are extrapolated into the future, and through design and planning, applied to the plans and processes of today.

Figure 2: Evolution of Data and Data Analytics in SCM

As technology is ever-evolving, it becomes increasingly difficult to stay ahead and incorporate technologies into existing infrastructure. Here are some pain points that supply chains face when data is not gathered at a sophisticated level:

Lack of Visibility:

Transforming raw materials into finished goods and delivering them to the end-user involves several third parties. The lengthier the supply chain process is, the greater is the complexity and number of third parties concerned.

And if more people are involved, communication becomes complicated and difficult. In an ideal situation, all third parties and stakeholders involved must have access to data at any point in time.

Higher Costs and Longer Process Time:

During international freight movement, logistics and supply chain expenses account for 5% to 50% of the product’s total cost. This includes and is accentuated by fuel cost fluctuations, delayed arrivals at ports, delivery delays, insurance, warehousing, custom duties, among others.

Topped with siloed systems, in the complex chain’s process, manual data entry is time-consuming, prone to human errors, impacts the trading partners’ assessment, and in turn, costs companies thousands.

Unresponsive and Poor Customer Service

Increased customer expectations, customers now demand more visibility in their deliveries and prompt customisation with changing business landscape.

Studies show 93% of consumers want to receive updates on their shipments, making visibility, not just a consumer demand but also an expectation.

In the recent decade, companies have started utilising data to visualise and analyse with Business Intelligence (BI) tools and track historical data to forecast demand, avoid risks, and manage schedules with advanced analytics.

Many companies are also infusing data and analytics capabilities into current practices. The forecast of demand, supply, transportation and staffing can create efficiencies across the board and help companies respond to and overcome disruptions. Simply having visibility and control of the supply chain can be a game-changer.

Recently, Singapore Government has also identified the scope of technology in the supply chain industry and has announced that it aims to bring an investment of $15 million for maritime trade. This new investment is for companies developing digital tools to automate logistics operations, from booking shipments on trucks, planes and ships to managing the flow of goods across global supply chains.

This combination of data and technology has been beneficial in enabling end-to-end visibility.

Others being:

Quicker Last-Mile Distribution:

The last leg of shipping is quite a notorious link in the whole supply chain journey. It is also the most significant cost driver.

Data advancement makes shippers possess clarity of the complete delivery process, thus optimising delivery strategies, building consumer patterns, and efficient route planning.

The latter is much dependent on operational tracks and weather conditions.

GPS-enabled sensors on delivery vehicles track and capture weather data, road maintenance data, fleet maintenance schedules, real-time fleet status and help companies advise optimisation accordingly.

Reduced Overhead Costs:

Real-time visibility promotes clear communication and fosters a collaborative approach between internal teams, key suppliers and service providers. These strengthen supplier relationships, simplify strategic sourcing, and support shared initiatives for growth and innovation.

Ultimately resulting in better demand forecasting, more accurate safety stock management, turnover rate optimisation, improved inventory management and reduced overhead costs.

Practical applications of data in the supply chain – Using smart sensors to drive supply chain innovation.

Smart sensors transform the physical world into digital insights used to create new value across the supply chain. Introduction of reliable IoT platforms and advancements in technologies that have both accelerated performance and reduced costs, traditional barriers to smart sensor adoption are eroding.

Improve Traceability :

RFID-enabled IoT sensors have varied applications. These modern tech devices are being used to track and trace perishable food, measure temperature and humidity during storage and transportation.

However, they are most popular and densely used by freight forwarders, logistics providers and transportation companies to identify abnormal shipping behaviour or weak links in business supply chains.

Monitor Container Conditions:

For freight partners, tracking delicate or perishable items is imperative. Real-time data from IoT-enabled sensors can communicate shipments’ location and give updates on the latest container conditions.

Supply chain managers can then be alerted of the problems and mitigate them before they become catastrophic.

Additionally, freight partners can track this data to predict and identify wherever issues tend to arise and remedy where there are likely to be broken processes.

Identify Security Concerns:

As demand for certain cargo assets, like trucks or ships with valuable goods, have increased, so has the risk of them being captured or stolen.

Companies can use real-time data to protect against theft. These high functioning, IoT-enabled sensors can monitor for dangerous driving conditions to assure both securities of their drivers as well as products.

Exception Management:

Exception management is an integral part of data management for the supply chain. With timely action, organisations can identify impending disruptive issues, manage the exceptions and save valuable time, resources and costs for all parties.

IoT-enabled sensors can monitor, generate data insights mitigating the impact of sudden, unexpected, and potentially disastrous disruptions to the supply chain.

What’s Next?

Since the Covid-19 pandemic hit, there have been many disruptions across industries all over the world. The need of the hour is a quick adaption by businesses to meet the modern world’s demand.

In addition to the increasing importance of technology within supply chain management, many technologies will impact the industry in the coming three to five years:

Robotic Goods-to-Person (G2P):

The current pandemic will push the demand for robotics G2P systems because they are cost-effective and improve productivity by utilising robots to perform low-value-added tasks like moving goods around.

As per Gartner, through 2023, demand for robotic goods-to-person systems will quadruple to help enforce social distancing in warehouses.

Real-Time Transportation Visibility Platforms (RTTVPs):

RTTVPs a growing part of the overall transportation technology market. Mostly owned and managed by third-party software vendors, these give end-to-end supply chain visibility.

By 2023, 50% of global product-centric enterprises will have invested in real-time transportation visibility platforms.

Artificial Intelligence:

Gartner highlighted that through 2024, 50% of supply chain organisations will invest in applications that support artificial intelligence and advanced analytics capabilities. The technology will enable the conversion of the vast data set into meaningful insights.

Leveraging the advanced level of supply chain data will be the key to drive a profitable business. Many companies have already been sharing data for many years with their trading partners. However, in the coming years, this will be the standard.

| Sign-up now to enjoy up to 12 months of free subscription of Tramés Learn how you can digitise your supply chains to save cost, improve efficiency and overall profitability by using the Tramés platform. No more emails, calls, texts or manual processes – you can easily collaborate, communicate and share information across your international supply chains, and logistics partners on one unified digital platform. Furthermore, signing up for Tramés and onboarding partners is hassle-free and can be done in a few simple steps. This enables quick and easy adoption for businesses of all sizes! Key features of the Tramés platform include a blockchain-enabled document repository, customisable workflow management, FTA advisory, track-and-trace and incident notification. This facilitates collaboration with all stakeholders and partners on a single platform and effectively streamlines and optimises your supply chain operations. |