Insights

Resilient Supply Chain Systems: Coping with Change

Trade fuels economies. And supply chains are the backbone on which trade runs. Given the number of participants in a supply chain ecosystem — including exporters, forwarders, importers, truckers, factories, distribution centres, customs brokers and carriers — are prone to various risks.

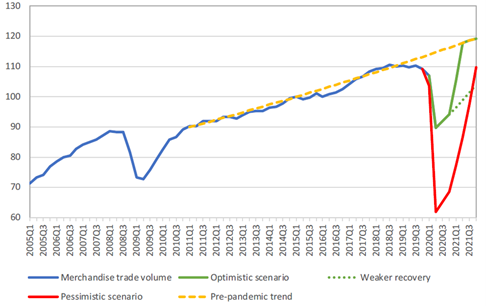

In the past few months, the COVID-19 outbreak has disrupted supply chains globally, throwing economies into a downward spiral. According to the World Trade Organization, merchandise trade volume shrank by 3 per cent year-on-year in the first quarter of 2020 (Ref. Chart 1). It is expected to have plummeted by around 18.5 per cent in the second quarter as lockdowns came into effect globally – impacting both global demand and supply of goods.

Chart 1: World merchandise trade volume, 2005Q1‑2021Q4

(Index, 2015=100) | Source: WTO/UNCTAD and WTO Secretariat estimate.

This raises the question of resiliency in our supply chains. In times such as these, a robust, agile and resilient supply chain ecosystem can help businesses withstand the shocks and ensure continuity.

With digitisation, businesses will be better equipped to handle most of their supply chain needs themselves, from planning and scheduling to tracking and ensuring the smooth flow of shipping milestones effectively. Businesses need to adapt, given the uncertainty being witnessed. In the current context, in many ways, digitisation can enable companies to collaborate more efficiently, functioning uninterrupted in the ‘new normal’.

Global Supply Chain Trends

Over the past four decades, rapid improvements in infrastructure connectivity and differing production costs across borders have significantly driven globalisation.

However, the 2008 Global Financial Crisis gave rise to the idea of ‘deglobalisation’, which in turn, more specifically gave birth to the theme of ‘decoupling’. These themes have gained greater importance in recent years, driven by rising wages in countries such as China, political wrangling over issues, and the ongoing US-China trade and tech war.

With the US imposing hefty tariffs on Chinese imports, several companies are looking to move their manufacturing base away from China – and some already have, with Vietnam being a notable beneficiary.

The focus on decoupling or ‘near-shoring’ has become sharper owing to supply chain disruptions brought about by the pandemic, which has exposed several vulnerabilities.

The COVID-19 crisis highlighted the importance of diversifying supply chains and producing goods locally to be self-reliant, especially for essential commodities. The twin trends of decoupling and localisation could well become salient factors influencing global supply chains.

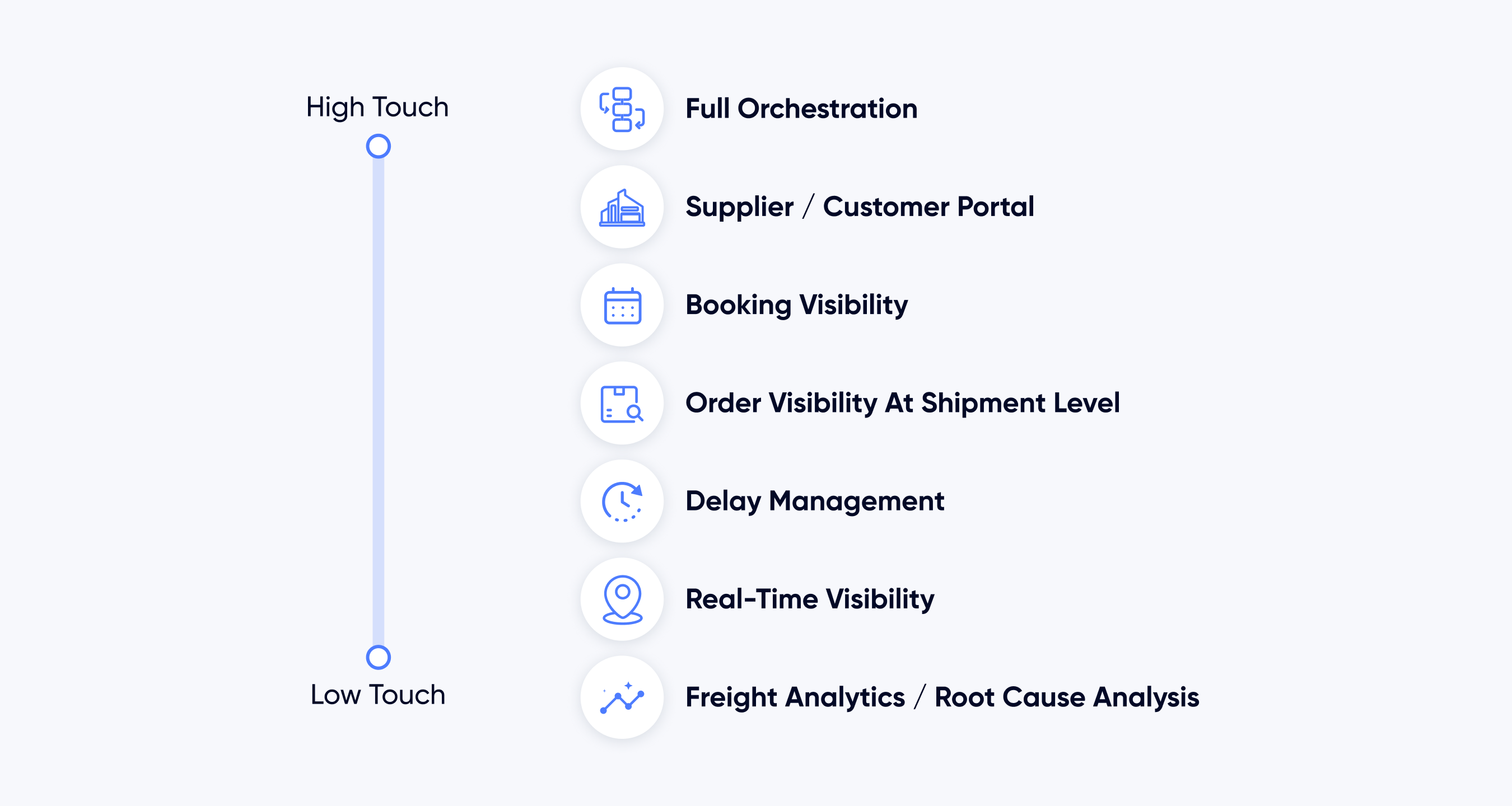

Many businesses have started to digitally orchestrate their supply chain to deal with all of this, from planning and scheduling to tracking and ensuring an integrated transportation workflow across partners.

Varied Approaches

Technology adoption in supply chain systems has brought organisations both productivity gains and cost savings. Several companies have set up innovation arms internally to digitise their supply chains and stay on top of developments in this space.

Although a novel approach, these endeavours are faced with challenges. First, these digital initiatives are limited in scope and more centred around the organisation’s requirements in question, rather than taking a holistic view of the entire supply chain ecosystem.

These internal digital initiatives often lack sufficient feedback from external stakeholders in the ecosystem, such as suppliers, buyers, and logistics partners. This introduces a bias in the system and can significantly impede scaling.

Startups have provided various solutions to address global supply chain challenges, but these have been mainly on a piecemeal basis. In other words, most are built to focus on managing pain points about one part of the supply chain. For instance, they might focus on assisting truckers, providing greater real-time visibility of a shipment’s location along the supply chain or optimising inventory management.

However, most fall short considering a holistic picture; thus, they generate limited insights that do not benefit the broader ecosystem.

How can this be done more effectively?

In our view, resilience in supply chains can be built by treating the whole as greater than the sum of its parts. Only through aggregating and analysing end to end workflows between all parties can we enable greater collaboration and, as a result, resilience in supply chains.

Every organisation has unique supply chain operations, and each can have specific needs for its business model. This makes customisation important. Therefore, it is vital to always listen to stakeholders, take feedback, and understand each of their requirements before providing customised solutions built to last and scale. As an enterprise-centric platform, we acknowledge supply chains’ complexities and avoid providing a blanket solution to all clients.

The second principle that helps achieve supply chain resilience, in our view, is providing an end-to-end solution. This is important to reap the full benefits of digitisation. If any stakeholder of the supply chain is not onboarded, digitisation becomes less effective as it will fail to provide a complete picture of the supply chain.

And third, to ensure industry neutrality, we have adopted a vendor-agnostic approach. This enables deep collaboration levels and is key to maintaining and strengthening partnerships with existing logistics stakeholders. Currently, we are integrated with several independent 3rd party data providers that enable our solution to provide an unbiased and holistic view.

Adopting the above steps and uncovering the weaknesses that exist in current supply chains, can better ensure continuity of business and hardiness in the face of global challenges, especially amidst the backdrop of the current pandemic.

Supply Chains of the Future

We will continue to see many more technological innovations that will make supply chains even more resilient and synergistic. Emerging technologies such as blockchain, artificial intelligence and IoT will enable data-driven decision making and significantly strengthen supply chains.

COVID-19 has exposed critical vulnerabilities of our supply chain ecosystem, owing to which the nature of supply chains are quickly evolving. In this context, businesses need to adapt better and strengthen their digital capabilities to address future supply chains.

This article first appeared in: Supply Chain Asia.