Insights

Creating Collaborative Innovation – An essential element to uplift the supply chain in the next decade.

As global supply chains continue to be more complex and fragmented, it becomes increasingly difficult to ensure collaboration and innovation between stakeholders. Conventional notions of innovation are often that change is to be driven from within an organisation to achieve revenue. However, with the contemporary globalised climate of the business world, companies are becoming reliant upon external actors to create possibilities for collaborative innovation across different aspects of the business cycle – from procurement to new product R&D to distribution and commercialisation.

It is rapidly becoming the DNA of most organisations that wants to be more productive, creative and efficient. Over the years, the process has evolved to be more complicated. Virtual teams communicate through a complex labyrinth of emails, chats, social networks, blogs, messages, forums, etc., to achieve the goals.

According to Steven Johnson, a science author & media theorist, “If you look at history, innovation doesn’t come just from giving people incentives; it comes from creating environments where their ideas can connect. “

Apart from raising awareness among key stakeholders, organisations struggle to establish a process and build a digital infrastructure that will facilitate cross-firm collaboration by remaining compliant to legal and regulatory frameworks.

How Collaborative Innovation can be a game-changer in supply chain?

Gartner’s Market Guide for Global Trade Management (March 2021) highlighted that the integration of disjointed applications that support siloed processes is often one of the biggest complaints of Global Trade Management (GTM) software end-users. The sheer number of stakeholders and the lack of integrated technology solutions are the key reasons why GTM applications have been used disjointedly, leaving little or no room for collaboration.

The relationship between buyer and supplier is complex and often takes time to develop but significant disruptions can quickly end the relationship too.

However, when collaborative innovation is done successfully, organisations can enjoy dramatic reductions in inventories and costs, together with improvements in speed, service levels, and customer satisfaction.

In Supply Chain Technology Predictions of 2021, Gartner has pointed out the inhibitions of businesses to rely on emerging supply chain management technologies to make decisions faster, without human intervention.

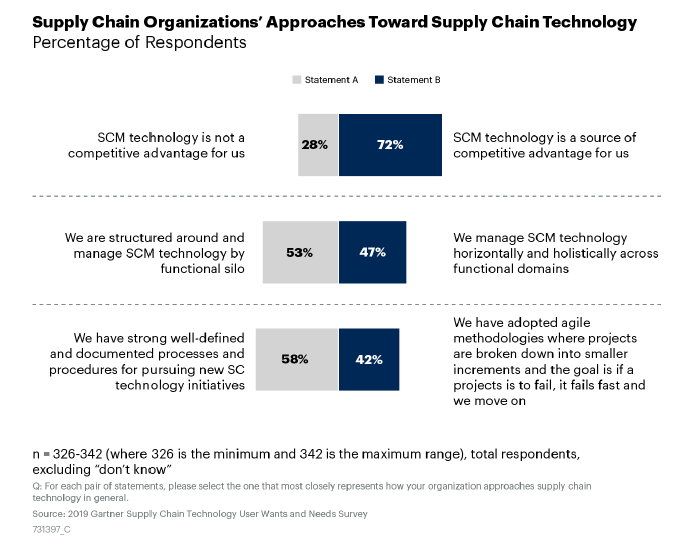

Although 72% of supply chain organisations view technology as a source of competitive advantage, the majority (53%) of companies continue to manage supply chain technology vertically around functional silos and not horizontally and holistically across functional domains.

Moreover, while the pace of change in the supply chain accelerates, only 42% of supply chain organisations have embraced agile principles as a way to accelerate innovation.

Enhancing Collaborative Innovation – Strategies

A unified platform that measures standard metrics and targets and jointly monitors progress can help companies avoid the misaligned incentives that damage so many collaboration efforts.

To build a successful process, organisations must turn collaboration into a core competency and take a thoughtful approach to select the suitable platform that complements the critical collaborative innovation strategies.

Strategic alignment to set the workflow for core and non-core activities

Various stakeholders should find shared corporate goals and values, map out innovation priorities and initiate a line of communication to build trust.

Strategic alignment can be promoted through a joint business planning approach to target areas of opportunity for collaboration, including growth, innovation, productivity, quality and margins.

For example, in a quest to develop more sustainable detergents, Unilever partnered with Novozyme, a significant enzyme supplier, to create new enzyme solutions.

The collaboration leveraged each party’s strengths, merging Unilever’s understanding of which types of stains and materials were most relevant with Novozyme’s reagent-optimisation capabilities.

The partnership resulted in two enzyme innovations that improved product performance, increased market penetration, and allowed the company to target premium-branded competitors. Moreover, the new formulation performed well at lower temperatures, helping customers save energy and reduce CO2 emissions.

A formal approach to collaboration with partners can be achieved through a centralised platform that allows easy onboarding of the stakeholders, consolidated communication and seamless information exchange.

Cross-functional engagement to develop relationships

Lack of dedicated resources from across the functions can cause complete failure of collaboration efforts.

For example, for a demand-planning attempt, the team ideally should comprise members from sales, finance, and supply chain for the manufacturer and purchasing, merchandising, and store operations for the retailer. However, establishing such cross-functional engagement should be well-managed to yield benefits.

All partners should clearly define each participant’s roles and responsibilities and set daily duties, including execution and monitoring of the efforts. Although it might take time to build trust and establish long-lasting relationships among the stakeholders, small and straightforward collaboration efforts that deliver quick results can help build momentum. A transparent, information sharing platform as a foundation can help partners understand and appreciate each other’s capabilities and commitments.

P&G has taken a step further in creating cross-functional teams solely focused on joint innovation with suppliers. By creating a practice of “open innovation,” P&G aimed to coordinate its efforts and leverage the skills and interests of people throughout the company to assess the competitive landscape, identify types of innovation that can help develop disruptive ideas, and identify relevant external partners.

For innovation to work, P&G has stressed the need to blend cross-functional teams that, in turn, integrate business strategy with operations—which requires a broad network of synergies.

Practice Compliance, Governance, and Performance Evaluation

Often organisations have relied on informal mechanisms to review progress and make business decisions.

However, lack of sufficient data makes it difficult to track and evaluate collaboration efforts, aligning purposes, remain compliant and build a formal governance structure.

Several forward-thinking organisations have created advisory board or councils to manage disruptive threats and risks to the collaboration ecosystem.

It serves as a neutral ground to provide high-level support and guidance to the stakeholders in setting business agendas and resolving significant issues. Technology solutions have enabled the councils to access data for assessments and evaluation on predefined performance metrics.

Toyota has been a prominent example of supplier collaboration, whose success can be explained in part by using clearly defined targets and supplier-performance metrics.

These are built into contracts that hold suppliers accountable for continued improvements in quality, cost, and delivery performance. The company governs supplier relationships using a steering committee staffed with relevant senior stakeholders from both organisations to define the scope and objectives of the collaboration, review progress, and remove roadblocks and resolve issues as they arise.

Conclusion

Supplier chain collaboration itself isn’t new. But in the given pandemic, it has taken on a much greater urgency and importance.

While the change in mindset and long-term commitment to derive value from the collaborative relationships are crucial, it is imperative to implement a digital solution to navigate the complexities of the collaborative innovation process.

Establishing a closer relationship can generate significant value for each partner and help supply chains become more resilient.