Insights

What is Supply Chain Visibility and Why Is It Important?

Supply chain visibility SCV is the systematic ability to track materials, components, and products downstream from the initial source to the customer. End-to-end SCV offers a clear picture of all inventory activities. This allows managers an opportunity to make contingency plans when things go wrong.

SCV strengthens the supply chain, ensuring that all stakeholders along the way have access to information. They can follow the status of the product and components as they move through the supply chain. Modern computing and internet technologies have made access to real-time information possible. Complex supply chains and high customer expectations have made this necessary.

With ready access to information, users have early warning of possible problems. This allows them to take action when they can still make a difference – essential in a complex and fast-changing global environment.

Global competition

In today’s world, many organizations operate globally. As competitive forces drive prices down, so companies must reduce costs. This has led to the outsourcing of processes, complicating the supply side. Add to this the long and often convoluted distribution channels where customers demand early gratification and customized products, and you get the picture.

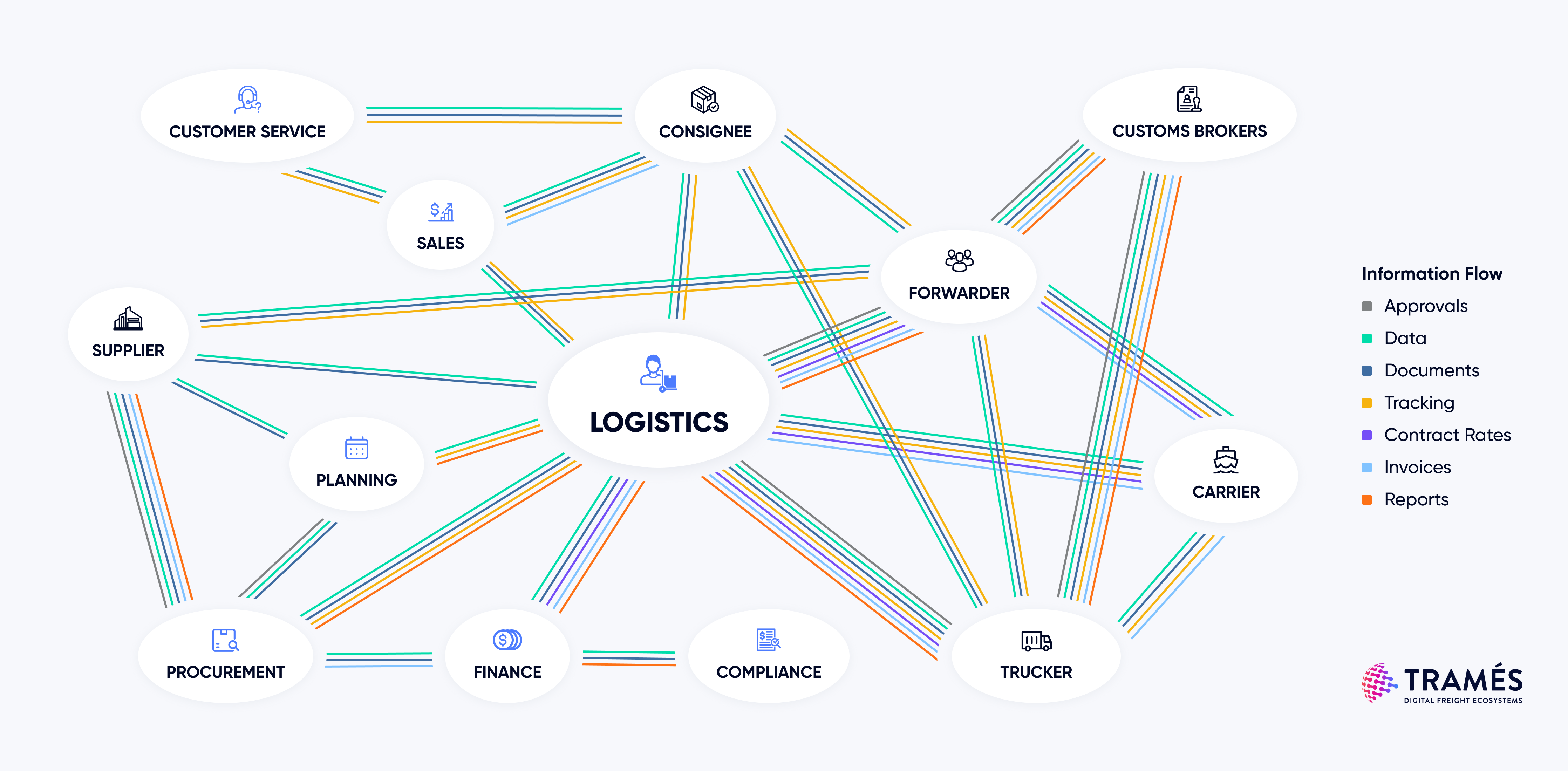

Many organizations use multi-modal transportation. A typical supply chain involves countless technologies, business partners, and logistics providers. Then, there’s the paperwork. If one of these components fails there is a knock-on effect across all operations that follow. Visibility allows stakeholders to make quick and informed decisions. Supply chain transparency enables the identification of inefficiencies and the application of solutions.

Government regulations and compliance have become increasingly complex. Nobody wants to fall foul of the law. For organizations that trade on a global scale, the regulatory environment is even more complicated. Since global operators must also take account of trade agreements and international law.

Supply chain disruptions during the pandemic have demonstrated the importance of SCV in the global market. As factories closed across the world, port congestion and delayed shipments also caused havoc. The well-publicized disruption to the automotive industry caused by the semi-conductor shortage is a case in point. In difficult times, SCV enables informed decisions to mitigate disruptions.

Increasingly demanding customers

Today’s customers expect shorter delivery lead times. They are also intolerant of mistakes and delays. They want high-quality products at the lowest price. In this environment, Businesses must become increasingly flexible. Customers can buy whatever they want, whenever they want across multiple channels.

SCV makes it easier for companies to meet these customer demands. It allows organizations to deal with supply chain disruptions before they affect the customer. If all else fails, companies can advise the customer of delays before they happen and make alternative delivery arrangements.

When shipment dates change customers expect immediate notification. SCV offers organizations a competitive advantage because, with it, they can better serve customers.

Efficiency improvements and cost savings

Technology can provide real-time information that facilitates supply chain operations. When supply chains are visible, organizations can plan and optimize. As the saying goes, you can only manage what you can see. The planning and optimization of the supply chain increase efficiencies and reduce costs. Supply chain management contributes a significant amount to any organizational budget.

When implemented effectively SCV enables the tracking of the product and its components from the source to the end consumer. Every organization in the supply chain will benefit from SCV. Supply disruptions negatively affect every subsequent operation. From transport to warehousing and production, all will suffer inefficiencies as a result. When goods fail to arrive, the workforce is not adequately employed and transporters may have to sub-optimize loads and routes.

When the supply chain lacks visibility, organizations must carry more inventory. SCV will reduce the need for inventory stockpiles across the supply chain. Cost reductions for storage, handling, and interest will follow. Capital tied up in inventory can be spent on alternative investments.

The benefits of Supply Chain Visibility

The benefits of SCV include;

- Better control of inventory

- Shorter cycle times

- Improved labor efficiency

- Time saved on tracking stock at suppliers

- Reduced costs

- Better customer service

All parties to the supply chain can benefit from SCV:

- Suppliers – can improve their inventory management because of backorder visibility. They can watch trends and make changes to improve customer satisfaction and the bottom line.

- Manufacturers – it is easier to plan production with SCV. The data facilitates production planning and procurement decisions for materials and components. Where seasonal trends exist, SCV makes it so much easier to plan the increases and decreases required to meet changing demand.

- Logistics providers – information provided by the system allows transporters to track cargo and run operations more efficiently

- The customer – in today’s world, customers want to track their cargo and know when to expect delivery. SCV enables real-time tracking, improving the customer experience.

Supply chain visibility as a strategic objective

SCV has become increasingly more important. In fact, a 2017 survey found supply chain professionals from 17 countries considered supply chain visibility an important strategic objective. It had moved in importance from 6thplace to third in the two years from 2015. Only 6% of firms believed that they had achieved this objective.

So, this begs the question why have so few organizations been unable to successfully implement full SCV. Companies face some real problems. These include;

- Unreliable data

- Demand forecast inaccuracies

- Lack of integrated information sharing within the supply chain

- Automated and manual operations that don’t integrate.

This shouldn’t happen where modern-day technologies exist. These include

- The Internet of things – used for tracking more than just location. They can also report on traffic patterns and ambient conditions.

- Artificial intelligence – helps to avoid waste and reduce the risk of loss and missed shipments. Predictive analytics help to manage inventory and automate warehouse operations. It converts real-time data into optimal planning decisions to improve supply chain efficiency.

- Geographic Positioning Software

- RFID Bluetooth technologies

In summary

Failure to supply on time can damage your finances, your business and your reputation. How far has your organization come in the quest for supply chain visibility?